For sewing, you need to understand machine needles, their structure, and their importance. How to select the right size and how to choose needle-type accordingly fabric. You’ll be also aware of precautions you need to follow to ensure safe sewing.

Sewing Needle

Of course, a needle is the most important element for sewing as it is the thing that penetrates through a piece of fabric, it guides the thread through the fabric.

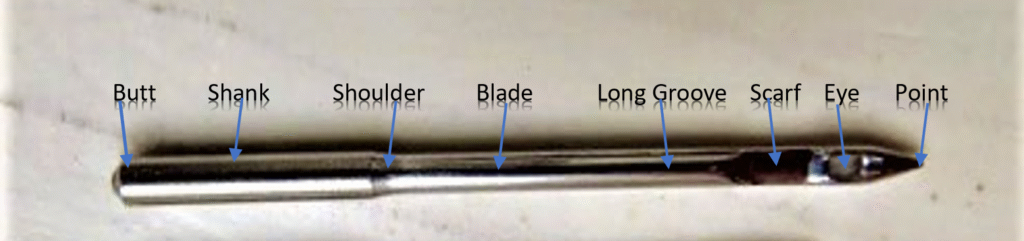

Structure of a Needle

Tip

The tip is the topmost part of a needle that pierces the fabric.

Point

The point is the bottom part of a needle, which extends from the eye to the tip. The point is the part that penetrates through the fabric. There are various kinds of needle points.

Butt

It is a small pyramid at the upper end of the shank. It is a shaped end. It fits into the needle bar.

Shank

Shank is the upper end of the needle. It is held in the needle bar by a needle screw. It can be cylindrical or flat. It is the largest and strongest part of the needle. So, it supports the rest of the needle. Depending on the sewing machine its diameter and length vary.

Blade

The blade is the main section of a needle. The long slender portion of the needle extends from the end of the shoulder to the eye. It has Long & Short Groove, Scarf, and the Eye.

- Long Groove: A long channel on the blade is extended from the end of the shank to the top of the eye called Long Groove. It is located on the side of the needle where thread enters the eye. It provides a protective channel through which the needle is drawn in and out of the material during the stitch.

- Short Groove: A short distance above and below the eye. It is located on the side of needle where thread comes out of the needle eye. It also provides protection to the thread while sewing thick fabrics.

- Scarf: It is a cut in the blade just above the eye. It allows the hook to pass closely between the needle and thread when forming the stitch.

- Eye: The eye of a needle is the opening part of the needle blade at the lower end through which the needle thread passes.

Shoulder

The shoulder is located in between Shank and the Blade. Here needle tapers down into the blade.

Choose a Needle!

Sizing of a Needle

The size of a needle is the diameter of the middle of the blade above the groove. It is measured in the hundredth of a millimeter. This means if the diameter of a needle is 1mm then the needle size is 100. Its unit is Nm. So the size is 100Nm.

Now, different brands use their own version of the size chart for needles. Singer uses a code that indicates a particular needle size.

If the needle is very fine for a thread, then the thread will suffer excessive fraction. If the needle is very thick there are chances of skipping stitches. So, yes choose your needle wisely.

Types of Needle Points

1. Cloth Points

Cloth points are used in sewing textile fabrics. These are two Types

- Round Point: As the name suggests the tip of the needle point is conical. Woven fabrics are sewn with this round point needle.

- Ball Point: The tip of the needle point is ball shaped, as the name is suggesting. These are used for knitting, in mesh, stretch, hosiery fanrics. Ball point needle slides between the yarns instead of piercing the fabric. So it reduces holes in the fabric.

2. Cutting Points

Cutting points are used for non-textile fabrics like leather. These materials are denser with no gaps. Cutting point needles cut a sufficient hole in the material for the needle blade to pass through the material without excessive friction.

Now Select!

- Needle: Choose round point needle for woven fabrics, ballpoint needle for knitting, cutting point needle for leather ad plastic types material. The size of the needle depends on the size of the yarns. For the thinner yarn choose fine needle and thread and vise verse. This will prevent damage to the material or thread or needle.

- Thread: Learn the fabric structure and content. Choose exactly same type of thread or atleast compatible with the fabric. For example use Cotton thread for Cotton clothes.

- Stitch Length: Simple to remember. Lighter Fabric – Shorter Stitch and Heavier Fabric – Longer Stitch.

More informations!!

Here is a table with details of needle size and SPI (Stitch Per Inch) need for a particular fabric.

| Fabric Type | Machine Needle Size | SPI |

|---|---|---|

| Sheer (Net, Voile, Chiffon, Organdy, etc) | 9-11 | 16-20 |

| Light (Thin Cotton, Crepe, Rayon, Silk, Taffeta, etc) | 11-14 | 14-16 |

| Medium (Linen, Cotton, Velvet, Corduroy, Heavy Muslin, etc) | 14-16 | 10-12 |

| Heavy (Denim, Tweeds, etc) | 16-18 | 6-8 |

Safety Precautions

- Sit straight, don’t lean forward toward the machine.

- Keep the work area neat and tie up your hair securely.

- Keep feet off from the treadle and turn off the power switch while setting up the machine

- Do not pull the fabric backwards, the needle can break and the splinters can harm you.

- Always keep your attention on your work.

- Don’t put your hand under the needle after you turn on the power switch.

- Keep your hands, scissors, etc away from the belt.

- Don’t run the machine very fast.

That's all for today! I hope you liked it (❁´◡`❁)